Lucitron®: Pioneering Flat-Panel Displays |

|||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|||||||||||||||

|

|

One sunny summer morning, Alan Sobel picked me up in his white station wagon. Alan was one of the Lucitron vice presidents. A few years before, Alan, Joe and Michael DeJule had founded the company. They had begun their research together at nearby Zenith. (3.)

On the way to Lucitron, Alan and I chatted about television electronics. And I then realized that the interview had already started. Then, smack in the middle of Northbrook, we turned up a quiet lane. On either side were rows of efficient, nondescript, brick buildings. Our destination was 1918 Raymond Drive. Glenbrook North High School was nearby, and the Metra train station was a short hike north. Anxiety. After we arrived, Joe Markin and Engineer Cary Stone (4.) joined us. Despite my anxiety, I passed my interview. A few weeks later, I signed on. That August, I switched to weekend consulting at Williams. Lucitron became my full-time gig. At Lucitron, Cary would be my boss. Handcrafted“Layer cake.” Inside Lucitron, expert technicians were handcrafting 35-inch plasma displays. For weeks, they stacked electrodes, layer-cake fashion, inside a glass box. Then they fritted the edges of the box, where hundreds of electrodes jutted out. Next, into the oven they popped this outlandish, electronic “cake.” Inside the oven, the seals baked air-tight. Afterward, they'd heft the huge display onto a four-wheel cart and roll into the pump room. There, a Sargent-Welch turbo pump would evacuate the tube and inject helium from a tank. Until seal-off, the tube required constant connection to our pump. Power supply and signal wires snaked to the tube from a wall-mounted cabinet. An engineer would start the eight power supplies and the screen would glow. Connecting a video cable to the electronics, the engineer would display a TV picture. About the Technology (5.)GEP-Tech 101. Lucitron designed and built the GEP, or Gas-Electron-Phosphor tube. (6.) The brand name (7.) for this new type of cold-cathode, plasma display was the Flatscreen®. Matrix wiring connected each array of row grids to the following array of 10. The same was true of each array of 16 column grids. Matrixing drastically reduced the drive electronics. Cary's electronics included a mere 16 column drivers. Only ten more drivers were necessary to operate the rows. (8.,9.)

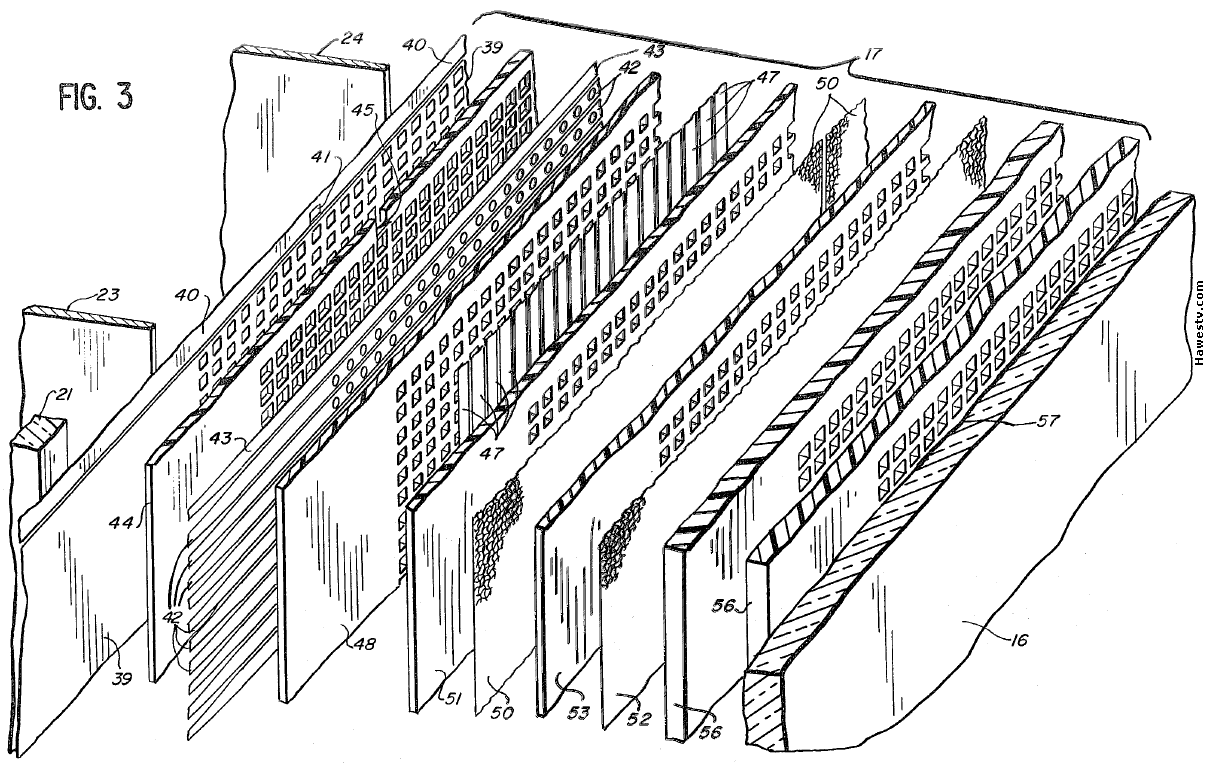

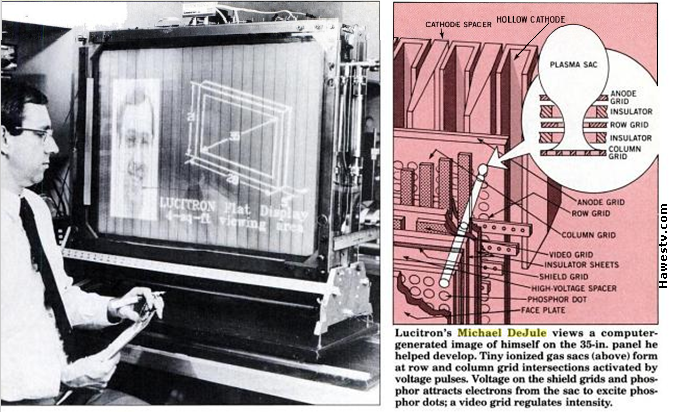

Lucitron panel from 1982, exploded view showing electrodes (U.S. Patent 4,352,101) How It Worked. See the figures, above and below. The hollow cathode served as the electron source for the tube. The anode accelerated electrons toward the row grid. (The cathode and anode don't appear in the figure above.) A helium plasma sac formed between charged row (#42) and column (#47) grids. The row grid moved the plasma sac vertically. The column grid moved the plasma sac horizontally. The video grid (#50) modulated display brightness, following the gray tones in the picture. The shield grid (screen grid) (#52) accelerated electrons toward the screen, exciting phosphor dots. The phosphor (#57) displayed a viewable picture on its luminescent surface. (10., 11., 12., 13.)

2-D, theory diagram of one grid section. Shows electrodes, but not spacers: This section could light one pixel. The 22 cathodes caused 22 plasma sacs to scan the screen at the same time. Each sac scanned the grids within a particular column. There were 22 columns, and each one had 16 column grids. (The columns were sometimes visible from an angle. In photos of the 34B tube on this page, you can discern 22 vertical divisions.) Plasma sacs scanned in a zig-zag pattern: Left to right. Then right to left. Incidental points... (14., 15.)

Michael DeJule & Flatscreen panel, in Popular Science (16.)

The Final ChapterThe venture capital didn't materialize. In fact, one of our main benefactors decided not to renew our funding. There were layoffs. On the day when I successfully demonstrated my power supply project, I lost my job. Necessity is the mother of Invention: Afterward, I expanded my consulting business to full-time. Soon, I snagged a gig at Motorola. Remaining Lucitron employees took a 25 percent pay cut. Most of them remained loyal to the company anyway. Party. Lucitron engineer Bob Mitchell famously had two birthdays. Despite aging at double the rate of everyone else, Bob was youthful. Nonetheless, nobody questioned his unusual situation. (Did he have two mothers?) Company policy was to celebrate both birthdays. Bob also hosted the company's 1985 Christmas-Hanukkah celebration. He and his wife invited both current and laid-off employees to the party at his home. Despite Lucitron's difficulties, we all shared an evening of great cheer. For those of us whom the company let go, this party was also a graduation ceremony. At the office, there was good news. After seal-off, Lucitron's first two 34B panels shipped to the U.S. Navy. (19.)

Go to Page: 1 2 3 Next Footnotes1. James T. Hawes (uncredited), “Flatscreen® Video by Lucitron®.” A New •Very Large •Thin •Flat Display Screen,” Lucitron, 1985. ▶Re: Photo of 34B Lucitron Flatscreen panel from Lucitron promotional flyer. Author wrote & published this flyer for Lucitron. Photo by Jeff Gwilliam. Isometric sketch of panel by Mike Klemm. Wooden frame for panel by Doug Yates. Typesetting. pasteup, and printing by Universal Press. (all uncredited in flyer.) 2. John Free, “Flat-Screen TV—Almost Here?” Popular Science, February 1986, 54-56. ▶Re: Joe Markin interview. 3. Ibid., 54. ▶Re: Researchers, formerly from Zenith Radio Corporation started Lucitron. 4.

Chicago Tribune, “Cary Stone, 1957—2017,” access on April 20, 2022:

https://www.legacy.com/us/obituaries/chicagotribune/name/cary-stone-obituary?id=2736330

5. James T. Hawes , e-mail message to Alan Sobel, May 23, 2009. ▶Re: Reminiscences about Lucitron colleagues & technology.6. Hawes (uncredited), “Flatscreen® Video by Lucitron®.” ▶Re: Term GEP, referring to Gas-Electron-Phosphor technology by Lucitron. 7. Ibid. ▶Re: Registered trademark Flatscreen® by Lucitron, Inc.® 8. Michael C. DeJule, “Flat Panel Display System.” patent US4,352,101 filed January 20, 1980 & issued September 28, 1982, p. 10, column 9. ▶Re: Matrixing reduces number of drives to 26: Columns only require 16, and rows only need 10. 9. John Free, “35-inch flat-screen TV is only 3 inches thick,” Popular Science, February 1986, 75. ▶Re: Matrixing: Only 16 column drivers and 10 row drivers are necessary. 10. DeJule, “Flat Panel Display System.” patent US4,352,101, Figure 3, p. 3. ▶Re: Exploded view of electrode structures (except for cathodes) in Lucitron flat-panel TV tube. Mr. DeJule assigned the patent to Lucitron, Inc., Northbrook, IL. 11. Ibid., Figure 3, pp. 3, 8, 9 & 10 (columns 6, 7, 8 & 9). ▶Re: Electrodes within Lucitron panel. 12. Free, “35-inch flat-screen TV,” 75. ▶Re: Theory diagram, showing exploded view, revealing internal grids. Michael DeJule interview. 13. Minor error in the exploded view. ▶Re: Leftmost "56" callout should read "55."14. Free, “35-inch flat-screen TV,” 75. ▶Re: Details about display scanning with 22 plasma sacs. Michael DeJule interview. 15. DeJule, “Flat Panel Display System.” patent US4,352,101, Figure 3, p. 3; p. 10 (columns 9 & 10); p. 11 (column 11). ▶Re: Scanning process, including priming pulses. 16. Free, “35-inch flat-screen TV,” 75. ▶Re: Michael DeJule interview. Includes black-and-white photo & mechanical drawing of tube grids. 17.

Chicago Tribune, “Rudolph Guzik,” access on April 20, 2022:

https://www.legacy.com/us/obituaries/chicagotribune/name/rudolph-guzik-obituary?id=2691431

18. Stephen A. Booth, “Electronics: Updates on the News,” Popular Mechanics, November 1986, 46. ▶Re: Black-and-white photo of 8" color demonstration panel. From Alan Sobel interview. 19. Booth, “Electronics,” 46. ▶Re: Lucitron shipped its first panel to U.S. Navy. Alan Sobel interview. |

Contents

Graphics

|

|||||||||||||

|

|

|